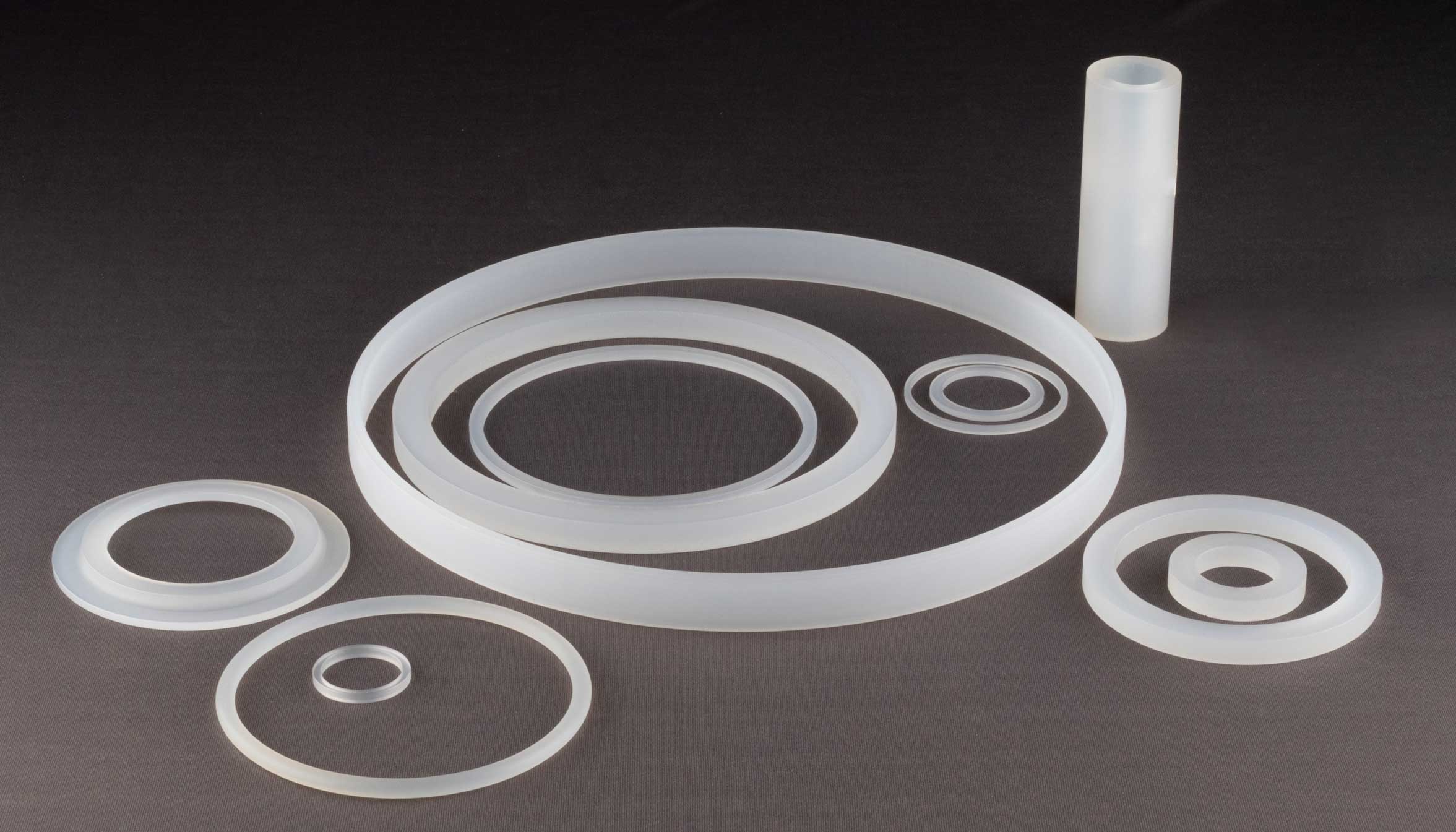

PFA (perfluoroalkoxy) is a tough, flexible fluoropolymer that is used for flexible tubing and fluid processing equipment when chemical resistance, high purity, and low stiffness are required. PFA has outstanding electrical properties including high dielectric strength, a low dissipation factor, and a low dielectric constant. The material has outstanding resistance to outdoor weathering. PFA has similar mechanical properties to FEP, but it has a higher service temperature than FEP and superior electrical properties compared with FEP.

PFA (perfluoroalkoxy) is a tough, flexible fluoropolymer that is used for flexible tubing and fluid processing equipment when chemical resistance, high purity, and low stiffness are required. PFA has outstanding electrical properties including high dielectric strength, a low dissipation factor, and a low dielectric constant. The material has outstanding resistance to outdoor weathering. PFA has similar mechanical properties to FEP, but it has a higher service temperature than FEP and superior electrical properties compared with FEP.

Common Applications:

- Pump housings and pipe linings

- Fluid handling and chemical processing equipment

- Tank linings

- Semiconductor wafer carriers, etc.

Fluorinated ethylene propylene (FEP)

Fluorinated ethylene propylene (FEP) is an inert, transparent and semi-crystalline fluorocopolymer consisting of hexafluoropropylene (TFE) and tetrafluoroethylene (HFP) repeat units.

It has outstanding thermal, electrical and chemical resistance, a very low coefficient of friction (self-lubricating and non-stick), and high dielectric strength. However, unlike PTFE resin, it is melt-processable using conventional injection molding and extrusion equipment.

FEP is ideally suited for applications where broad chemical resistance, high durability over a wide service temperature range, excellent dielectric properties and a low coefficient of friction are required or are advantageous.

Common Applications:

- Thermoformed components

- Heat-sealable bags

- Electrical insulation cables and connectors

- Lining for pipe and chemical processing equipment.

PFA (perfluoroalkoxy) is a tough, flexible fluoropolymer that is used for flexible tubing and fluid processing equipment when chemical resistance, high purity, and low stiffness are required. PFA has outstanding electrical properties including high dielectric strength, a low dissipation factor, and a low dielectric constant. The material has outstanding resistance to outdoor weathering. PFA has similar mechanical properties to FEP, but it has a higher service temperature than FEP and superior electrical properties compared with FEP.

PFA (perfluoroalkoxy) is a tough, flexible fluoropolymer that is used for flexible tubing and fluid processing equipment when chemical resistance, high purity, and low stiffness are required. PFA has outstanding electrical properties including high dielectric strength, a low dissipation factor, and a low dielectric constant. The material has outstanding resistance to outdoor weathering. PFA has similar mechanical properties to FEP, but it has a higher service temperature than FEP and superior electrical properties compared with FEP.